How to produce a coil heat exchanger

As we all know, coil heat exchangers are very important part of a air cooled chiller and air source heat pumps. How does a factory produce coil heat exchangers? Below are total 9 different procedures to maintain superior quality products.

1. Material preparation (copper tube, end plate, side plate, middle support plate, short U-head, gas / liquid tube, liquid distribution tube)

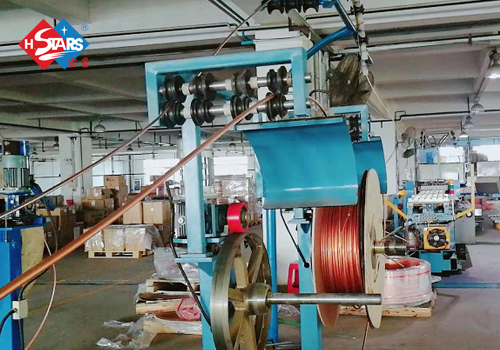

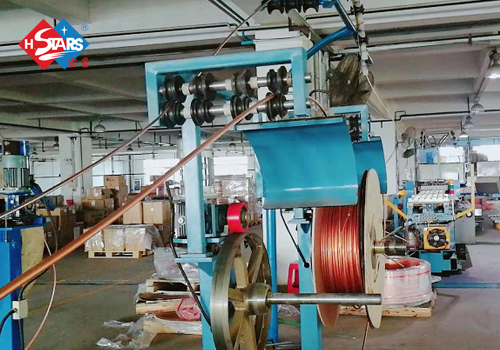

2. Fin stamping (punching machine, fin die) mainly produces corrugated fins or louver fins according to requirements, including multiple rows and multiple sections of fins.

3. Copper tube cutting (bending machine, cutting machine) according to the need to discharge long U-tube, straight tube.

4. String tube, pre-assemble the fin, copper tube and end plate together manually

5. Tube expansion (horizontal tube expander, portable tube expander) is mainly to expand the pre-assembled copper tube and finned copper tube into a coil with high heat exchange effect, and complete the copper tube at the same time Cup expansion and flaring

6. Welding (welding equipment) welds the relevant copper fittings and coil into a whole for nitrogen filling protection according to the process requirements, forming a closed and safe circuit

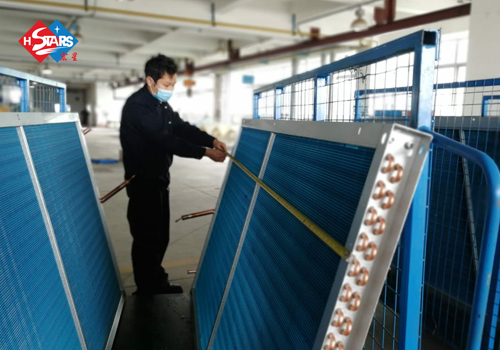

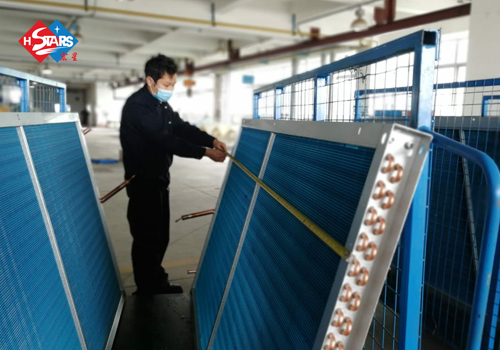

7. Appearance inspection (Vernier caliper and micrometer) Perform visual inspection on the welded coil according to the inspection standard and make a record

8. Leak detection (water detection line) According to the process requirements, the completed coil is checked for gas leakage and pressure resistance, the inspection pressure is 3.0Mpa, and the pressure holding time is 3min

9. Put in warehouse. Labeling and certificate of qualified products, and packaging protection

评论

发表评论