Singapore Plastic Wrap Factory Project

Provide automatic temperature regulating chilled water system for plastic wrap production line

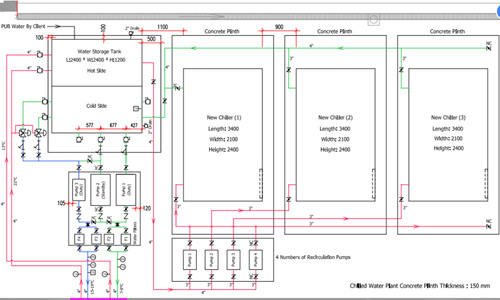

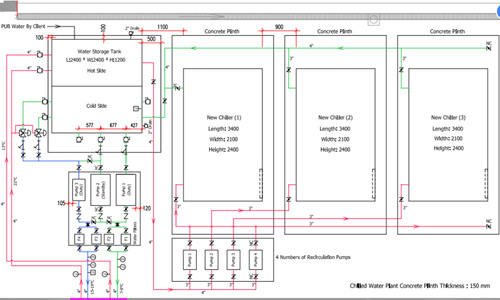

Project Design Drawing

Project Chiller Specification :

3 sets of 300kW Anti-Corrosion Type Air-cooled Chiller with water pump and tank designed as all in one unit to save labor cost at site.

(2) Chiller adopts 304 stainless steel frame design. In humid and rainy environment,the operating life of the unit can reach more than 15 years;

(3) Chiller adopts flooded type evaporator, the heat transfer effect is 30% higher than the ordinary evaporator;

(4) The heat exchange tube of the chiller is made of 316 stainless steel, which can effectively anti corrosion from sea water ,to ensure the chilled water in contact with the plastic wrap with food-grade. It also can reduce the subsequent maintenance cost.

(5) The chiller compressor and condensing fans are variable-frequency control, which can freely match the variation of refrigerating capacity demand on the production line. The chiller can save 30% of the electricity all year around .Chiller Pictures

3 sets of 300kW Anti-Corrosion Type Air-cooled Chiller with water pump and tank designed as all in one unit to save labor cost at site.

(2) Chiller adopts 304 stainless steel frame design. In humid and rainy environment,the operating life of the unit can reach more than 15 years;

(3) Chiller adopts flooded type evaporator, the heat transfer effect is 30% higher than the ordinary evaporator;

(4) The heat exchange tube of the chiller is made of 316 stainless steel, which can effectively anti corrosion from sea water ,to ensure the chilled water in contact with the plastic wrap with food-grade. It also can reduce the subsequent maintenance cost.

(5) The chiller compressor and condensing fans are variable-frequency control, which can freely match the variation of refrigerating capacity demand on the production line. The chiller can save 30% of the electricity all year around .Chiller Pictures

Project Site Picture

评论

发表评论