The Solution of Cold Water of Concrete Mixing Station

1.Background of the project

Temperature-controlled concrete is required for large-scale pouring of large hydro power dams, nuclear power, high-speed iron, and high-rise building foundations. During the concrete mixing process, the internal volume of the concrete hydration heat increases, especially the heat generated by the stirring under high temperature conditions is higher. In the subsequent curing or low temperature, the interior of the concrete will be caused by the thermal expansion and contraction. The volume is reduced, and cracks usually occur in this process. Therefore, the initial pouring temperature of the concrete should be low, reaching the limited temperature of the building design unit, and thus the quality of the project. Cold water is used in the construction to cool the concrete!

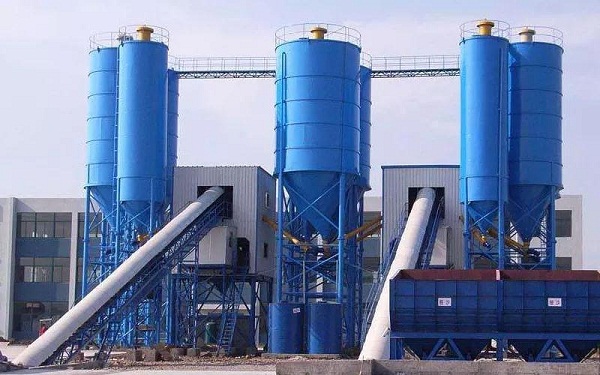

In order to meet the engineering needs of such customers, Stellar provides a professional concrete mixing station cold water system. The stellar concrete mixing plant cooling industrial chiller directly supplies 0-10 °C chilled water, or 0-2 °C ice water mixture, which can fully meet the requirements of the national standard for quality inspection of concrete cooling. Widely used in the national railway bureaus, highway bureaus, construction bureaus, water and electricity bureaus and other large concrete mixing, such as: high-speed rail, tunnels, hydro power, dams, hydro power stations and other civil construction concrete cooling.

2.The solution

As a strength manufacturer in the refrigeration equipment industry, Stellar Refrigeration provides two high-efficiency concrete mixing station cold water system solutions for different environmental needs:

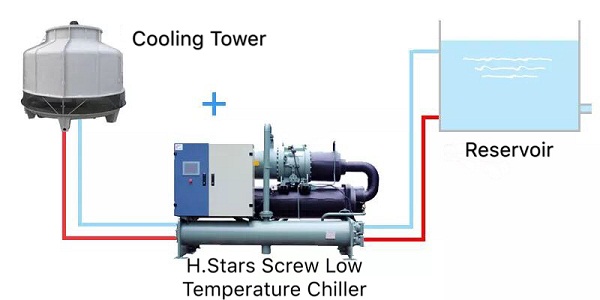

1) Screw chiller + cooling tower

This program utilizes the original reservoir of the mixing station and is adapted to local conditions.

2) Integrated cold water system

The special chiller for concrete mixing station adopts brand-name screw compressor as the cooling main unit. Combined with the automatic control system, it can automatically select one stage of cooling or multi-stage cooling according to the inlet and outlet water temperature or summer and winter operation mode. It is energy-saving, time-saving, stable and environmentally friendly. Features, energy saving 10-35% than traditional concrete cooling system (chiller ice unit), while reducing the cost of investment.

Concrete special chiller can provide: 1 ton / hr ~ 150 ton / hr concrete chilled water or ice water mixture, designed and produced according to the type of mobile chiller station, the whole machine is shipped in container mode, only the user is in the industrial area. With the power supply, connect the pipes and use them.

In order to meet the actual production needs of our customers as much as possible, we can carry out research and development, production and supporting units according to the customer's on-site construction requirements.

评论

发表评论